By Dan Balkin

The first high speed detachable lift built by the Austrian company Doppelmayr was installed in … some famous ski resort in Europe? Nope. It was installed in Breckenridge CO in 1981. High speed lifts were a revolution and continue to evolve. They went from seating four, to six “the six pack,” and now can seat as many as eight. State of the art high speed lifts have heated seats and “bubbles” that can be pulled down over the chairlift to protect skiers from high winds and inclement weather. HoliMont’s flagship Exposition high speed detachable quad chairlift was built by Doppelmayr and installed in 2012. Chad

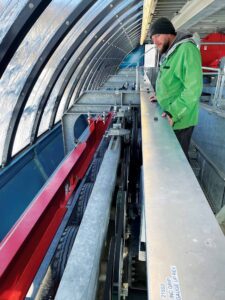

in the upper Exhibition lift terminal. The detached

chairs are being pulled along beneath the

spinning tires.

Jacoby, HoliMont’s Lift Maintenance Supervisor, offered to show us the inside workings of the base terminal above the loading zone for the Expo chair. Even as it passes through the base and summit terminals, the main cable continues to always spin at the same high speed. That is why the magic word for a high-speed lift is “detachable.” In other words, within the terminals, the chairs are being moved along by a completely different mechanism than by the cable that whisks us up the mountain. The secret? There is a very rigid, black “traction plate” attached to the skyward side of the arm where the chair grips the cable. When a chair enters the terminal and detaches from the high-speed lift cable, a long series of small tires are spinning at a precisely calculated position where they engage with the traction plate and propel the chair slowly forward. With remarkable synchronicity and the use of many sensors to keep the chairs evenly spaced, the tires keep the chairs moving toward a bullwheel which turns the chairs toward the other side of the terminal (the side where passengers are loaded on the chair). The traction plate reengages with another long series of small tires where the chairs are now progressively sped up in preparation for being reengaged with the rapidly spinning chair lift cable. Watching all this progress from the terminal elevated above the loading area is like seeing an engineering ballet where the chairs all make precise, in-sync movements.

HoliMont GM Ed Youmans shared some interesting facts about high-speed lifts: A high-speed lift is roughly twice as expensive as a fixed grip lift – but it moves twice as fast. A high-speed lift is ascending at 1,000 feet per minute. Every six seconds, passengers load and unload from a high-speed lift. On a fixed grip lift, the chairs are spaced approximately 55 feet apart, while on a high-speed lift they are twice the distance, 110 feet apart. This means that even though the high-speed lift moves twice as fast, because it only has half the number of chairs as a fixed grip lift, they both bring 2,400 people up the mountain per hour. Put another way, a high-speed lift has half the number of people riding, but they are moving twice as fast. Without longer lift lines, a skier can get more runs in on a high-speed lift. The high-speed lift has an enormous safety advantage because the slow speed of the “detachable” chair as it goes around the bull wheel at the bottom and top of the hill makes it safer to load and unload passengers. High-speed lifts, however, have five times the moving parts of fixed grip lifts, meaning that maintenance is magnified versus an old-fashioned fixed grip chairlift. Chair lifts, like life, are a series of compromises.

Due to the enormous weight and tension a chairlift cable endures, it must be shortened at least once in its lifetime to remove excess slack. Remarkably, there are only FIVE persons in the entire U.S. that can shorten and resplice a chair lift cable. Two cable splicers from Missouri were at HoliMont this summer and, with the help of our full-time employees, removed six feet of slack and masterfully respliced the cable. HoliMont? Missouri? High Speed Chair? Sounds incongruous, but it’s also a reminder we are interconnected and need one another.